Understanding NEMA connectors is important for anyone working with electrical systems in North America. A NEMA connector chart shows the different types of power plugs and receptacles used for AC mains electricity, helping you choose the right connection. With various configurations and ratings, these connectors ensure safe and efficient power delivery.

In this blog post, you will find specific NEMA part numbers, pin configurations, and their uses. You'll learn about the differences between straight-blade and locking types, and how each is used in residential and commercial settings. This knowledge will help you make smart choices when selecting electrical equipment.

Explore the details of NEMA connectors and see how the right choices can improve safety and functionality in your projects. Whether you are an electrician, technician, or DIY enthusiast, understanding this chart is a valuable skill that can enhance your work.

Understanding NEMA Connectors

NEMA connectors are designed to create safe and reliable electrical connections. They standardize plug and receptacle types, making it easier to connect various electrical devices across different contexts.

What is a NEMA Connector?

A NEMA connector refers to a specific type of electrical plug and receptacle defined by the National Electrical Manufacturers Association. Each connector has a unique designation that combines letters and numbers, indicating its configuration and electrical specifications.

For example, the designation L5-30R indicates a receptacle type with a 30-amp rating.

NEMA connectors are widely used in both residential and industrial settings. You can find them in household appliances, commercial equipment, and even construction tools. Their standardized design helps ensure that electrical devices can connect safely without the risk of misconfiguration.

The Importance of NEMA Standards

NEMA standards play a crucial role in electrical safety and compatibility. The National Electrical Manufacturers Association sets these standards to ensure that different electrical components from various manufacturers can work together reliably.

These standards help to prevent unsafe conditions that could arise from using incompatible connectors. By following NEMA guidelines, manufacturers create devices that meet safety and performance requirements.

This reduces the risk of electrical fires, equipment damage, and personal injury. Standardized connectors also simplify installation and maintenance, as you can trust that devices will fit and function correctly.

Standard NEMA Connector Types

NEMA connectors come in various types, each designed for specific applications and environments. Understanding these standard types helps you choose the right connector for your electrical needs.

Straight Blade Connectors

Straight-blade connectors are some of the most common types you will encounter. They are typically rated for currents from 15 to 30 amps and work with voltages of 125 or 250 volts.

Here are a few types:

- NEMA 5-15: Commonly used in household appliances, this 15-amp plug is widely found in homes.

- NEMA 5-20: Similar to the 5-15 but rated for 20 amps. It features a T-slot for added compatibility.

- NEMA 6-15: Designed for 250 volts, suitable for higher-rated gear, like certain power tools.

These connectors are designed for easy use and compatibility with ungrounded, polarized, and grounded devices.

Locking Type Connectors

Locking type connectors provide a secure connection to prevent accidental disconnection. They are ideal for outdoor or industrial settings where movement is common.

Some common locking types include:

- NEMA L5-15: A 15-amp plug that locks into its receptacle, suitable for sensitive equipment.

- NEMA L6-30: Rated for 30 amps and used in high-power applications like generators.

- NEMA TT-30: This 30-amp connector is often used for RV power supplies. Buy 30 Amp NEMA TT-30P to Dual TT-30R Splitter Power Adapter, 3 Foot now❗

The locking mechanism ensures that the connection remains intact, even in rough conditions.

Twist Lock Connectors

Twist lock connectors are known for their unique design that requires you to twist the plug to lock it into place. This feature enhances security and stability.

Key types include:

- NEMA L6-20: A 20-amp twist lock used mainly in commercial settings and industrial applications.

- NEMA L5-30: This 30-amp plug is designed for connections requiring higher power.

- NEMA 6-30: This connector supports 30 amps and is suitable for heavy-duty equipment and appliances.

Twist lock connectors are particularly useful in environments where vibrations or movement could cause conventional plugs to disconnect.

NEMA Connector Chart

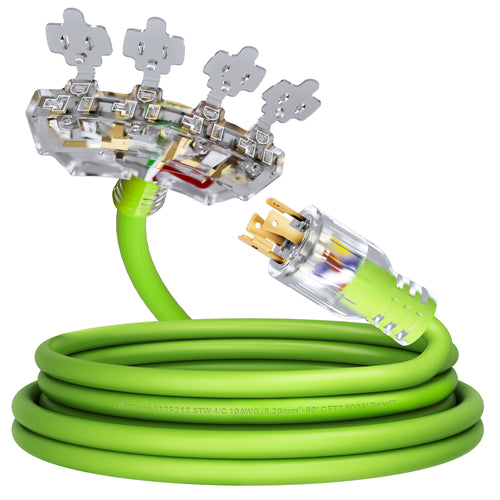

Photo: https://www.americord.com/nema-charts

The NEMA connector chart is an important tool for anyone working with electrical systems. It provides clear information on different connector types, configurations, voltage ratings, and their specific applications. Knowing how to use this chart will help you select the right connector for your needs.

Overview of the NEMA Connector Chart

The NEMA connector chart lists various electrical connectors and their configurations. Each entry includes:

- Connector Type: Identified by a code such as NEMA 5-15 for a common household plug.

- Voltage Ratings: Indicates the maximum voltage the connector can handle, for example, 125V or 250V.

- Amperage Ratings: Shows the current capacity, such as 15A or 50A.

- Applications: Describes where the connector is typically used, like in homes, commercial settings, or industrial equipment.

This chart helps you quickly determine which connector fits your appliances or devices based on their voltage and amperage requirements.

How to Read the NEMA Connector Chart?

Reading the NEMA connector chart is straightforward. Follow these steps:

-

Identify the Connector Type: Look at the left column to find the type you need, like NEMA 5-15P for plugs.

-

Check the Voltage Rating: Move across the row to see the voltage listed—this will guide you on compatibility with your electric systems.

-

Look at Amperage Ratings: This information helps you ensure that the connector can safely handle the current.

For example, if you see NEMA 14-50P, it means it is a 50 amp, 240V plug suitable for heavy-duty appliances like electric vehicles. By understanding these elements, you can effectively choose the right connector for your situation.

NEMA Plug Types

NEMA plugs are crucial for ensuring safe electrical connections. Different types correspond to specific voltage and current requirements. Understanding these plugs helps you choose the right one for your applications.

Overview of NEMA Plug Types

NEMA plug types are categorized based on their design and specific applications. Each type has a designation that reflects its intended use. For example, some plugs are designed for standard residential power, while others are suited for commercial or industrial settings.

Typically, these plugs can handle varying voltages, usually ranging from 120 volts to 600 volts, and different current ratings up to 60 amperes. Knowing the correct type enhances safety and performance in your electrical projects.

NEMA 1-15 and NEMA 5-15

NEMA 1-15 plugs are two-pronged and typically used in older devices and appliances. They handle a maximum of 15 amperes at 125 volts. Common applications include lamps and light-duty electronics.

In contrast, the NEMA 5-15 is a three-pronged plug recognized for its grounding pin. This plug type provides enhanced safety by reducing the risk of electrical shocks. It can also support 15 amperes at 125 volts and is used widely in residential outlets for devices like computers and kitchen appliances. Both types ensure a reliable connection for everyday use.

NEMA 6-20 and NEMA 6-30

NEMA 6-20 and NEMA 6-30 plugs are designed for higher power needs. The NEMA 6-20 can handle up to 20 amperes, making it suitable for air conditioners and power tools that require more energy. It’s also rated for 250 volts.

The NEMA 6-30 deals with even greater needs, handling up to 30 amperes at the same voltage. These plugs are often found in industrial settings and used for heavy-duty equipment. They have unique blade configurations that prevent mismatching with lower-rated plugs, ensuring a safe connection.

NEMA L5-30 and NEMA L6-30

NEMA L5-30 and L6-30 plugs feature a locking mechanism, providing a secure connection in places where movement can cause disconnections. The NEMA L5-30 is rated for 30 amperes at 125 volts, often used in commercial applications.

On the other hand, the NEMA L6-30 is for 30 amperes at 250 volts. These plugs are typical in industrial environments for machines and other high-power equipment. Their design prevents accidental disconnection, which is vital for ongoing operations in commercial settings.

NEMA Connector Applications

NEMA connectors are widely used in various settings, including residential, commercial, and industrial environments. Understanding their applications can help you choose the right connector for your needs.

Residential Use

In residential settings, NEMA connectors are essential for powering a range of devices. Common types include:

- NEMA 5-15R: This standard outlet is used for many household appliances like lamps and computers.

- NEMA 5-20R: This outlet can handle larger devices like microwaves and air conditioners.

Choosing the correct NEMA plug is vital for safety. For instance, using NEMA 1-15P for light-duty devices ensures a secure connection. Additionally, HVAC systems often rely on NEMA 14-30 or 14-50 connectors for larger units. Ensuring compatibility between devices and outlets is key to preventing electrical failures.

Commercial Applications

NEMA connectors play a critical role in commercial buildings as well. They are primarily found in offices, retail spaces, and restaurants. Common configurations include:

- NEMA 5-20R for larger appliances like vending machines.

- NEMA 6-50 for equipment requiring more power such as commercial ovens.

These connectors ensure reliable operation of vital equipment. By selecting the correct NEMA connector, you improve electrical safety and equipment efficiency. For example, NEMA 14-20 and 14-30 connectors are commonly used for charging electrical vehicles at commercial charging stations.

Industrial Settings

In industrial environments, NEMA connectors are vital for heavier machinery and more robust applications. Commonly used connectors include:

- NEMA 10-30 and 10-50 connectors for older equipment.

- NEMA 7-20 and 7-30 for hazardous locations.

These connectors ensure the safe and continuous operation of industrial equipment. For high-voltage applications, NEMA 18-50 and 18-60 connectors are often chosen.

Selecting the right NEMA connector minimizes downtime and enhances operational safety. It’s essential to follow safety guidelines depending on the machinery to prevent any electrical hazards.

NEMA Adapters and Compatibility

When using NEMA connectors, understanding adapters and compatibility is crucial for safe and effective electrical connections. Adapters can bridge gaps between different types of plugs and receptacles, but safety should always be your priority.

Using Adapters Safely

To ensure safety when using adapters, select ones that are rated for the intended load and voltage. Check the specifications to confirm they match your devices. Using an adapter rated for a lower voltage can pose fire hazards or damage your equipment.

Safety Tips:

- Always verify the amperage rating of the adapter.

- Avoid using multiple adapters in a single connection, which can lead to overheating.

- Inspect adapters regularly for wear or damage.

Consider common configurations, such as the NEMA 5-15P for standard household outlets or NEMA 6-15P for heavier appliances. These can often be adapted for various uses while maintaining safety.

Compatibility Between Different NEMA Types

NEMA connectors are designed with specific configurations to prevent unsafe use. Compatibility varies based on the NEMA type, such as 5-20P and 6-20P. These connectors are designed to fit only specific receptacles.

For example:

- NEMA 5-15P fits a 5-15R but cannot connect to a 6-20R.

- NEMA 14-20P is compatible with both 20A and 15A receptacles, but the connection must be rated for the highest amperage required.

When using adapters, make sure to check the compatibility chart to avoid issues. Using incompatible connectors can lead to power failures or safety risks. Always consult the manufacturer's specifications for guidance on using adapters with your devices.

Installation and Maintenance Tips

When installing NEMA connectors, ensure you select the right type for your needs. Common types include NEMA 1-15 and NEMA 5-20. Check the voltage and current ratings before proceeding. This guarantees safe operation.

Follow these steps for safe installation:

- Inspect the power cord for any damage.

- Ground the connector properly to prevent electrical shock.

- Follow manufacturer instructions closely for specific requirements.

Regular maintenance is vital for the longevity of your NEMA connectors. Conduct inspections to catch any signs of wear early. A simple checklist can help:

- Check connections for tightness and corrosion.

- Inspect the body of the connector for cracks or damage.

- Ensure the grounding is intact.

Setting a schedule for routine inspections enhances safety. Consider how often the connectors are used when deciding the frequency. Regular checks help you avoid unexpected electrical failures, keeping your appliances and devices functioning properly.

Conclusion

Understanding the NEMA connector chart is essential for safely connecting your electrical devices. This chart provides vital information about different types of NEMA plugs and receptacles.

Key Points:

- NEMA standards prevent unsafe connections and ensure that devices receive the correct power.

- Familiarize yourself with the various NEMA plug types, such as the NEMA 14-50 used for heavy-duty applications.

Usage Tips:

- Always check the voltage and amp ratings on the chart.

- Ensure compatibility between plugs and receptacles before making connections.

Using the NEMA connector chart helps you make informed choices. Regular reference to this chart will keep your setup safe and efficient. Always follow safety guidelines when working with electrical connections to prevent hazards. By following these points, you can effectively use NEMA connectors in your projects.

Must Read Articles 📖:

- Common Questions About NEMA 14-50 Plugs Answered

- Understanding NEMA 14-50 and NEMA 14-30 Outlets and Plugs

Frequently Asked Questions

This section addresses common questions about NEMA connectors. You will learn about different types of NEMA ports, their configurations, and how they compare to other standards.

What are the different types of NEMA ports?

NEMA ports come in various styles for different applications. Common types include straight blade and twist-lock connectors. These connectors are used in homes, businesses, and industrial settings.

What is NEMA vs IEC connector?

NEMA connectors are standard in North America, while IEC connectors are used internationally. NEMA is often used for higher power applications. IEC is preferred for devices that require a universal connection.

What is the NEMA configuration?

The NEMA configuration refers to the specific design and electrical ratings of the plugs and receptacles. Each configuration has a unique code based on voltage and amperage. This helps ensure compatibility with different devices.

What does NEMA mean on a plug?

NEMA stands for National Electrical Manufacturers Association. This organization sets the standards for plug and receptacle configurations. When you see NEMA on a plug, it indicates the specific type and ratings for safe use.

How are NEMA 5-15P plugs different from other NEMA standards?

NEMA 5-15P plugs are rated for 15 amps and are commonly used for general household appliances. They have two flat parallel blades and a grounding pin. Other NEMA standards may handle higher voltages or different configurations.

What should I know about NEMA twist-lock plug compatibility and usage?

NEMA twist-lock plugs are designed to provide a secure connection. They must be twisted to lock in place, preventing accidental disconnections. Always check compatibility with sockets before use to ensure safety.