![Industrial Ethernet: What Is It & How Does It Work [Ultimate Guide]](https://cdn.shopify.com/s/files/1/0252/3326/0653/files/Industrial_Ethernet_1024x1024.png?v=1723540169)

Industrial Ethernet (IE) uses standard Ethernet technology in industrial settings. It provides reliable and real-time communication needed for automation and manufacturing. Unlike standard Ethernet for general networking, Industrial Ethernet is made for the tough conditions in factories and industrial environments. It ensures networks work well under demanding conditions.

As manufacturing and automation grow, Industrial Ethernet becomes even more important. It supports advanced systems that need fast and consistent data exchange among machines and devices. This guide will cover key protocols related to Industrial Ethernet, explain how it differs from commercial Ethernet, and explore its benefits for your business.

By reading on, you will learn about the technologies that drive modern industrial networks. Discover the various protocols like EtherCAT, PROFINET, and Modbus TCP that power these systems. This knowledge will help you understand industrial networking and improve your organization's efficiency.

What is Industrial Ethernet?

Industrial Ethernet is a networking technology designed for use in industrial settings. It builds on standard Ethernet protocols to support reliable communication between devices.

This technology enables robust and real-time communication. It is essential for connecting equipment like sensors, controllers, and actuators in automation and control systems.

Key features of Industrial Ethernet include:

- Determinism: Ensures data is transmitted promptly.

- Real-time control: Supports immediate responses to changes in the environment.

- Durability: Designed to operate in harsh conditions, such as extreme temperatures or vibrations.

Common protocols used in Industrial Ethernet are:

- EtherCAT

- PROFINET

- EtherNet/IP

These protocols enhance standard Ethernet for demanding industrial tasks. They allow for greater reliability and efficiency, which is critical for manufacturing processes.

The Four Major Protocols in Industrial Ethernet

When working with Industrial Ethernet, understanding the main protocols is crucial. Each protocol has unique features, benefits, and applications that make it suitable for different automation and control tasks. Here are four of the leading protocols you should know.

1. Modbus TCP/IP

Modbus TCP/IP is one of the earliest and most widely used protocols in industrial settings. It is simple and easy to implement, which contributes to its popularity. This protocol uses a client-server model, allowing multiple devices to communicate over Ethernet.

Key Features:

- Interoperability: Modbus TCP/IP supports a wide range of devices from different manufacturers.

- Simplicity: The protocol is straightforward, making it easier for engineers to adopt.

- Flexibility: It can serve various applications, from basic monitoring to complex control tasks.

One limitation is its non-deterministic nature, which may not be suitable for time-sensitive applications.

2. EtherCAT

EtherCAT stands for Ethernet for Control Automation Technology. It is designed for real-time control and is known for its high speed and efficiency. With EtherCAT, data is passed through devices without requiring them to read and process it individually.

Key Features:

- Determinism: EtherCAT can achieve very low latency, making it ideal for time-critical applications.

- Performance: It supports hundreds of nodes with minimal delay.

- Flexibility: It allows for both distributed and centralized control architectures.

This protocol is often used in manufacturing and robotics, where real-time data exchange is essential.

3. EtherNet/IP

EtherNet/IP is an open standard protocol that is widely adopted in industrial automation. It uses standard Ethernet and Internet Protocol (IP) for communication, offering strong integration with IT technologies.

Key Features:

- Wide Adoption: Many vendors support EtherNet/IP, ensuring good interoperability.

- Scalability: You can easily expand networks without major changes.

- Integrated I/O: It allows for both control and information to flow seamlessly on the same network.

EtherNet/IP is particularly effective in environments requiring both control and monitoring.

4. PROFINET

PROFINET is a protocol developed by the Profibus and Profinet International group. It was designed for factory automation and process control, providing high levels of flexibility and performance.

Key Features:

- Real-Time Communication: PROFINET supports both real-time and non-real-time data transmission.

- Integration with Existing Systems: It allows for easy integration with previous systems, which is vital during upgrades.

- Standardization: As a globally recognized standard, it promotes interoperability among devices from different manufacturers.

This protocol is especially useful in applications that require high reliability and flexibility.

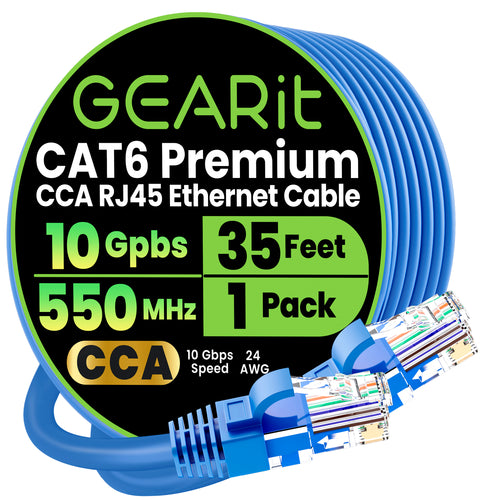

Types of Industrial Ethernet Cables

Industrial Ethernet cables come in different types, each with unique specifications and applications. Here are some common ones:

-

Cat5e: This cable supports data rates up to 1 Gbps and is suitable for most basic industrial applications. It is cost-effective and works well for shorter distances.

-

Cat6: Offering higher performance, Cat6 cables can transmit data at speeds up to 10 Gbps for distances up to 55 meters. They provide better shielding, reducing interference in noisy environments.

-

Cat6a: This is an enhanced version of Cat6, capable of 10 Gbps speeds at distances up to 100 meters. It has improved shielding, making it ideal for high-density wiring.

-

Cat7: With the highest performance, Cat7 cables support data rates up to 10 Gbps and beyond. They include more rigorous shielding and can reduce crosstalk in industrial settings.

Each type is designed for specific needs. When selecting an industrial Ethernet cable, consider the required speed, distance, and the environment where it will be used.

Operational Technologies in Industrial Ethernet

In industrial settings, operational technologies (OT) play a crucial role in connecting and managing equipment for efficient processes. Specific systems and communication methods ensure reliable data exchange and control in real-time.

PLCs and Automation Systems

Programmable Logic Controllers (PLCs) are central to industrial automation. They oversee machinery and processes by receiving inputs from sensors and executing commands. With Ethernet-based communication, PLCs can integrate into larger networks, enhancing flexibility and control.

Key features of PLCs include:

- Reprogramming capabilities: PLCs can be easily reconfigured for different tasks.

- Compatibility: They work with various sensors and devices, enhancing interoperability.

- Scalability: You can expand systems by adding more PLCs as needed, making them ideal for growing operations.

Real-Time Communication and Determinism

Real-time communication is essential for industrial systems to make quick decisions. Deterministic networking ensures that messages are delivered within a guaranteed time frame. This is critical for applications like robotics or conveyor systems, where delays can lead to safety issues or production downtime.

To achieve real-time capabilities:

- Use of protocols like EtherNet/IP and PROFINET enables rapid data exchange.

- Prioritized messaging allows critical information to take precedence, reducing latency.

- Network redundancy measures reduce the chance of communication loss, ensuring consistent operation.

Power over Ethernet in Automation

Power over Ethernet (PoE) simplifies network cabling by allowing power to be delivered along with data through the same cable. This is particularly useful in automation, where devices like cameras and sensors need both power and connectivity.

Benefits of PoE in industrial settings include:

- Reduced cabling costs: Fewer cables lead to lower installation complexity and cost.

- Flexibility in device placement: You can place devices wherever needed without worrying about power outlets.

- Centralized management: PoE switches can monitor and control power to connected devices, improving management efficiency.

Applications of Industrial Ethernet

Industrial Ethernet plays a crucial role in various sectors, enabling efficient communication and control. It enhances automation processes and supports advanced manufacturing initiatives.

Automation and Control Systems

In automation and control systems, Industrial Ethernet enables real-time communication between devices. This is vital for applications like:

- Manufacturing Automation: It connects machines, allowing for synchronized operations and reduced downtime.

- Robotics: Ethernet protocols facilitate fast data transfer, improving response times and coordination among robotic systems.

- Process Control: Real-time monitoring of production lines ensures consistent quality and performance.

With deterministic communication, systems can handle large data volumes while maintaining low latency. This setup enhances reliability in critical tasks, ensuring that operations run smoothly.

Smart Factories and Industry 4.0

Industrial Ethernet is key to the development of smart factories and Industry 4.0. Here’s how it impacts these initiatives:

- Integration of IoT Devices: Industrial Ethernet supports various Internet of Things (IoT) devices used in production, streamlining data collection and device management.

- Advanced Analytics: Enhanced data flow allows for real-time analysis and insights, helping you make informed decisions quickly.

- Predictive Maintenance: The system can track equipment performance, predicting failures before they occur. This leads to timely maintenance and minimizes interruptions.

Choosing the Right Cable for Your Application

Selecting the right Industrial Ethernet cable is crucial for your setup. Here are key factors to consider:

Environmental Conditions

- Temperature: Ensure the cable can operate within your facility's temperature range.

- Humidity: Choose cables that resist moisture, especially in damp areas.

- Chemicals: If your environment has harsh substances, opt for cables designed with chemical resistance.

Mechanical Stress

- Flexibility: For moving parts, select cables that can withstand bending and twisting.

- Abrasion Resistance: Look for rugged cables if they will be exposed to wear and tear.

Transmission Requirements

- Speed: Determine the data rate needed. For most industrial uses, Cat 5e or Cat 6 cables are suitable for up to 1 Gbps.

- Bandwidth: Make sure the cable can handle your bandwidth demands without signal loss.

Certification and Compliance

- Check for cables meeting industry standards like UL or IEC. Compliance ensures safety and performance.

Installation Best Practices

Follow these best practices to ensure a successful Industrial Ethernet setup.

-

Plan Cable Routes

Plan the cable routes carefully. Avoid areas with high interference, like electrical equipment or motors. Also, make sure you allow for bends without exceeding the minimum bend radius. -

Use the Right Cable

Choose cables designed for industrial environments, like PROFINET. These options typically have shielding to protect against noise. -

Secure the Cables

Use proper cable management tools such as clamps or trays. This keeps cables organized and protected from damage. -

Label Cables

Clearly label each cable at both ends. This will help with future maintenance and troubleshooting. -

Terminators

Ensure correct termination of cables. Poorly made connections can lead to signal loss. Follow the manufacturer's standards for the type of connectors you use. -

Testing

After installation, test each cable with a cable tester. This helps confirm proper connections and functionality. Look for any signal loss or errors. -

Use Managed Switches

Incorporate managed industrial switches wherever possible. They enhance network performance through features like loop prevention and diagnostics.

Conclusion

In conclusion, Industrial Ethernet is a robust and reliable networking solution designed to meet the demanding requirements of industrial environments. It ensures high-speed data transfer, real-time communication, and enhanced durability, supporting various applications from manufacturing to automation.

Understanding how Industrial Ethernet works and its benefits can help businesses optimize their operations and increase efficiency. For all your power connectivity needs in PC, networking, audio, video, and business applications, GearIT provides top-quality solutions. Visit GearIT today to explore their extensive range of products and enhance your Industrial Ethernet setup for optimal performance and reliability.\

Must Read Articles 📖:

Frequently Asked Questions

Below are answers to some common inquiries that will help clarify the importance and use of Industrial Ethernet in industrial settings.

What is the difference between Industrial Ethernet and regular Ethernet?

Industrial Ethernet is designed for tough factory environments. It has better resistance to temperature changes, humidity, and electromagnetic interference compared to regular Ethernet. This makes it more reliable for running machines and devices in production settings.

What are the benefits of using Industrial Ethernet in my factory?

Using Industrial Ethernet can improve communication between devices, increase data transfer speeds, and enhance diagnostics. It allows for real-time monitoring and control, helping to streamline operations and minimize downtime. This can lead to higher efficiency and productivity in your factory.

What is the difference between PROFINET and Industrial Ethernet?

PROFINET is a specific standard that operates on Industrial Ethernet. It focuses on automation and control in industrial environments. While both use similar technology, PROFINET adds features for real-time communication, making it suitable for time-sensitive applications.

What is the speed of Industrial Ethernet?

Industrial Ethernet supports various speeds, including 10 Mbps, 100 Mbps, and even 1 Gbps in some setups. The speed you choose can depend on the specific needs of your application and the type of equipment you are using.

What is the difference between TCP IP and Industrial Ethernet?

TCP/IP is a communications protocol used for data transfer over networks, including the internet. Industrial Ethernet incorporates TCP/IP but adds specifications and features suited for industrial applications. This ensures robust performance and reliability in challenging industrial conditions.